Derbyshire Mills

Various types of water Mills have been used over a long period of time developing from the laborious use of stone querns worked by hand to more productive operations.

In the First century BC the poet Antipatier of Thesalonica the author of over a hundred epigrams in the Greek Anthology was known for being the first to mention use of the waterwheel in a poem. He tells of an advanced overshot wheel watermill and praised it for its use in grinding grain and the reduction of human labour: He wrote –

“Cease from the grinding ye women who toil at the Mill.

Sleep late, even if the crowing cocks announce the dawn.

For Demeter has ordered the Nymphs to perform the work of your hands

And they leaping down on top of the Wheel, turn its axles which,

With its revolving spokes turns the heavy Nysyrian Millstones.”

One of the earliest types of Mill, three of which were sited on Hadrians Wall, was due to Vitruvius and known as the Vitruvian Mill.

Germany had used Water Mills from early times and is accredited with bringing the principle to England, first being established on the rivers of Kent and East Anglia where they were user to grind corn.

An early mention of a Mill being used to grind corn appears in a Charter granted by Ethelbert of Kent to the Monks of a Dover Monastery in AD762.

The Domesday Book records over 5,000 Corn Mills mostly in South or East Trent and Severn and the Vicar of Ecclesfield who dies in 1478 mentions grinding by Water Power.

Evidence of low breastshot waterwheels from the 11th century have been found at King’s Mill, Castle Donnington and by the 14th century the vertical undershot wooden wheel had grown in popularity.

After about 1200AD windmills had become increasingly common, particularly in places where the water supply was limited and they were also built to supplement existing watermills. However by the 16th century water power was the primary source of motive power throughout most on Europe, except in low countries where the windmill was predominant.

There are four types of waterwheel – undershot, overshot, breast shot and back shot named in relation to where the water hits the wheel. Until the late 18th century wheels were normally made of wood as was the powering mechanism but when cast iron became available it was incorporated into shafts, waterwheel paddles and gears etc.

Following the population explosion between 1750 and 1850 corn mills became more numerous to meet the increased demand to produce food. ~Many design improvement also were made to increase efficiency.

After nearly 2,000 years steam power followed by electric power saw the small water powered mills become obsolete by the end of the 19th century.

| Abney – Corn Mill SK21479 The mill was located in the valley of the Bretton Brook, on the north side of the stream. Abraham Walker was the miller here in 1857 but the mill was in disuse within a few years of that date. |

| Alderwasley Mill SK332538 The mill stood on the Pendleton Brook, a tributary of the River Derwent. It does not appear on Burdett’s map but is shown on the 1836 Ordnance Survey map. Millers are listed as Store in 1891 and Peacock in 1904. The mill must have ceased to work soon after this date |

|

Allgreave – Folly Mill SJ971664

The mill was probably built by Abraham Day in about 1790. He built three mills on this site, the first and second were washed away by floods and according to tradition his wife told him it would be ‘folly’ to build a third and that if he did so she would go to bed and never get up again. Nevertheless Day persisted with his intention and, true to her word, his wife retired to bed so it is said, and stayed there until she died in 1826 aged 76. Another theory about the mill’s name concerns its remoteness and inaccessibility for raw materials. It was located deep in the valley of the Clough Brook, on a tributary of the Dane, in a wooded gorge at a place called Gideon (or Gibbon’s) Cliff and was locally considered ‘folly’. When the mill was advertised for letting in 1849 ‘with water power and machinery for finishing paper’ it was thought prudent to amend the name to Folly Grove Paper Mill. If the mill was built at the end of the 18th century it would have been used to make paper by hand with waterpower used to drive a Hollander. Rags were the only raw material capable of being used to make paper prior to the middle of the 19th century. In the 18th and 19th centuries the manufacture of paper was subject to a complicated taxing structure. Excise collectors lived permanently at the site of Folly Mill and Bosley Parish register shows an entry in 1820 for the baptism of two sons of Jenkin Jones, an excise man of Wincle. The excise records for 1816 show that Thomas Hope was the master paper maker at both Folly Mill and Whitelee Mill in Wincle, although it is not known whether he was owner of this property or a tenant of Abraham Day. The mill was used for the manufacture of coarse brown or blue paper of the type used in the past by grocers and ironmongers and though apparently worked originally by Day himself, in 1825 was being operated by Thomas Hope of White Lee, who also ran the other Wincle paper mill. In 1835 Abraham Day died in his 95th year, but Thomas Hope and subsequent members of the Hope family continued to operate Folly Mill until 1860 when records show that ownership had changed to John and Matthias Slack. However, by this time paper making had become a fully mechanised continuous process using machines invented by the Fourdrinier brothers in Staffordshire and the hand made process used at Folly Mill became uncompetitive. Folly Mill continued to operate until 1867, but in 1868 it was listed as “not in work” and in 1869 as “unoccupied”. |

|

Alport – Corn Mill SK223646

Alport Corn Mill on the River Lathkill is of ancient origin and a mill is recorded here 1159-60. The Alport Mill is mentioned many times in the ‘Haddon Charters’; once as early as 1208, when a Henry de Hotot was ‘tenant of an oxgang of land and a quarter of the mill’. Owned by the Duke of Rutland and leased to S. and E. Johnson Ltd. for cattle, pig and poultry foods. Alport Mill was last worked properly in about 1925. A portion of the older building has been removed and some additions made. The breast-type waterwheel, approximately 4ft wide, with iron buckets, is still in position and inside the mill are five pairs of millstones. |

|

Alstonefield – Lode Mill SK146551

Lode Mill on the River Dove is a former corn mill, also now forms part of a farm. The name Lode Mill is thought to be a possible corruption of ‘Lead Mill’ as the mill was multi purpose and used for lead smelting, grinding red and yellow ochre and also corn. |

| Alstonefield – Milldale SK139547 long demolished; a millstone lies on the ground and there are remains of the weir and short mill race. The mill was on a small island in the River Dove . It possibly dates back to the 17th century of even earlier. |

| Ambergate – Saw Mill SK352517 – Built in 1856 by John Linacre |

| Ashbourne – Cotton Mill SK159455 |

|

Ashford in the Water – Black Marble Mill SK190694

At Ashford-in-the-Water and in some other places the extraction and working of marble was an important local industry for a period of about 200 years. Not actually marble in the true geological sense, the substance is in fact an impure form of limestone, usually dark grey, but becoming black in colour and highly decorative when polished. Evidently known in prehistoric times – a dressed slab was found in a tumulus on the hill north of Ashford called Fin Cop – the marble was certainly being worked around 1690 when it was mentioned in some Chatsworth accounts. In 1748 Henry Watson established his marble mill at Ashford and the material was used for a wide variety of ornamental purposes including interior building work -particularly at Chatsworth-and in the making of such things as table tops, statues, vases and trinkets. The chief source of the marble was the Arrock Quarry (SK 191694), now overgrown, fenced off and dangerous, a short distance from the A6 on the minor road to Sheldon. Originally quarried, and later mined underground, the blocks were taken across the river to the mill where, by the use of water power, the marble was sawn to the required shapes, ground and polished. In 1832, some years after Watson’s death in 1786 which preceded several changes of hands, a mine was opened by a Mr Oldfield across the valley in the Rookery Plantation (SK 190695) and marble extracted here from deep inside the hillside also supplied to the mill. Towards the end of the century, however, interest declined and the industry suffered from the competition of other materials. Though turbines had been installed during the later years, marble working at the Ashford mill ceased in 1905. For a number of years afterwards the premises were used as a barytes mill by the Via Gellia Colour Company, and then for timber; part of the site was later absorbed in the construction of the A6 road. A dwindling amount of inlay work from reserves of the material still in hand continued in certain places for a number of years after closure of the mill. At Ashford-in-the-Water Rowland Holmes made combs from tortoiseshell in a small mill constructed as a secondary user of the marble mill leat. Some ruins of this building remain adjoining the site of the former marble works, slightly downstream. |

| Ashford in the Water – Comb Mill SK190696 – The Ashford in the Water Comb mill was downstream of the marble works and was operated by Rowland Holmes in the 1850s. Ruins and old pictures indicate a single-storey stone building, 10 ft x 18 ft inside, with large windows. |

| Ashford in the Water – Flewitt’s Corn Mill SK198695 – Flewitt’s Corn Mill at Ashford in the Water was owned by the Duke of Devonshire until the 1950s; leats from the River Wye passed on either side of the mill which formerly had two waterwheels, a wooden one and an iron one |

|

Bakewell – Lumford Mill SK 212691 |

| Bakewell – Marble Mill SK220686 – marble extracted from the Blackstone Hollow Quarry at SK200678 was worked at a mill on the Wye near Bakewell Bridge. |

| Bakewell – Saw Mill built 1751 probably originally as a corn mill but later converted to a saw mill. It was demolished in 1997 after becoming a ruin. |

|

Bakewell – Victoria Mill SK212687

The Victoria Corn Mill beside the Buxton road (SK 216687) probably occupies the site of a mill recorded at Bakewell in the Domesday Book. The large gritstone building with its iron-framed windows, dating from the late eighteenth and early nineteenth centuries, formerly belonged to the Duke of Rutland; it was rented by Messrs Bailey from about 1890 and owned by them from around 1920. Powered by water from the River Wye, the mill was used for grinding corn for local farmers up to the end of World War II and afterwards as a store for feeding stuffs. |

|

Bamford Mill SK205833 |

| Baslow – Barbrook Smelting Mill SK268734 Ruins of former lead smelting mill west of the Barbrook. At the apparent site of the Barbrook slag mill (SK 268734), west of the stream close to the A621 road, there are considerable remains in the form of ruins of tumbled stone and also discernible, beneath a growth of herbage and scrubby trees, a depression in the ground which was the mill pond, with the possible route of the leat leading to it. |

Baslow – Hodgkinson’s Corn Mill SK250724 – Hodgkinson’s Corn Mill, which had a bakehouse adjoining, was on the Derwent below the weir (SK 250724); there was almost no mill race, the water being fed direct from the weir. The waterwheel was removed in the 1930s. |

| Baslow – Marples’ Corn Mill SK 272721 was in use as such in the 1880s but by 1900 was a sawmill. |

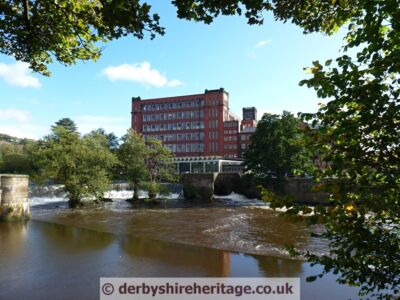

| Belper Cotton Mills SK345480 A very early cotton mill was worked by two horses in Paddlewell Yard, c 1730, by Joseph Robinson, spinning raw cotton brought from Manchester by pack horse. Strutts’ spinning mills, (later English Sewing Ltd), by Belper Bridge also has a weir and flood controls. North Mill, 1804, is the oldest. West Mill, 1798, South Mill, 1812, and Round Mill, 1813, were demolished. Gun embrasures were built in the bridge over the road, for defence against the Luddites.Jedediah Strutt began building mills in Belper from 1776. The original North Mill was completed in 1786 but was destroyed by fire in 1803. Its replacement, the present mill, was built in 1804 on the earlier mills foundations by Jedediah’s eldest son William Strutt and is one of the oldest surviving example of an industrialised iron framed ‘fire-proof’ building and is now recognised as one of the most important industrial buildings in the World, and as such, is a central point in the Derwent Valley Mills World Heritage Site.The mill was the most technically advanced building of its time, incorporating an iron frame and brick arches, to make the building “Fireproof”. Considerable thought was given to the individual building components. For instance, iron beams were ‘turtle-backed’ that is, deeper in the middle where they were under the greatest stress. |

| Birchover Eagle Tor Mill believed to have been an ancient one which stood at SK 232627. The mill, which had previously been worked by Messrs Johnson and unused for a number of years, was demolished in the 1950s. |

| Blackwell – Corn Mill – The former Blackwell Corn Mill (SK 113727), disused since before living memory. |

| Bolsover – Corn Mill SK478707 – had a steam engine in 1845. |

Bolsover windmill – Tower windmill in local stone with brick capping. The cap, sails and shaft are missing. Small detached brick chimney on a local stone base to the side. The mill was built about 1793 but probably little used after 1895. |

| Bradbourne Mill SK201521 Disused from about 1923 but an attempt to get it working again in 1940 failed. It has a date of 1726 and is shown on Burdett’s survey of 1767. |

| Bradford Dale corn mill – The river powered at least one corn mill – there was formerly a corn mill at SK 199636 on the River Bradford, where its site is marked by some slight ruins. |

| Bradwell – Saw Mill Former saw mill at SK174811. The waterwheel was driven by the Bradwell Brook and was removed in the early 1900s. |

| Bradwell – Bump Mill SK176817 An old mill called Bump Mill (bump being a coarse kind of cotton), dating from the eighteenth century, was at SK 176817, but has long been demolished. |

| Bradwell – Stretfield Mill SK177821 One of three cotton mills in Brough. The business failed at the end of the nineteenth century and the premises were used for a variety of purposes including making combs from ox horn and being used as a hostel for cement workers, before being refurbished and used for offices and light industry. |

|

Brough – Corn Mill SK183826

The mill is not included in the Domesday Book in 1086 but in 1199, Phillip de Strelley, of nearby Hazelbadge Hall,  was assessed (for tax) on a mill valued at £4-0-0 per annum. King John later gave the mill to Phillip, requiring that he provide a valet whenever the king came to the area to hunt. In 1421 the mill and various estates were granted to Richard Vernon of Haddon. By 1625 Brough Mill was owned by Rowland Moorwood of Castleton but was sold by him to the Eyres of Hassop Estates for £20-0-0 on the 3rd of May, 1625 and remained in their possession for 286 years. The mill is shown on Burdett’s map, and on most maps up to the present day.The three storeyed stone corn mill, with stone flagged roof, was also used as a saw mill, powered by one of the wheels. Millers included Ben Kirk in 1835, Sarah Kirk in 1842, with G. Mortimor in 1855. They were followed by Thomas Carter from 1876/81 but in 1885 the tenancy of the mill was taken over by William Eyre and in 1911 Hassop Estates decided to sell the mill at public auction when William purchased it for £1000.In 1900, William’s son Marmaduke joined the company and became a partner in Wm. Eyre and Sons. He was later joined by his brother William, who also became a partner in the business, and the mill continued lo thrive. However disaster struck when, in mid-winter 1924, a fire broke out in the mill, possibly starting from the kiln which was fuelled by gas, when some lead pipes melted. The building interior was virtually gutted, although both wheels were saved. Electricity was generated until around 1950 when abstraction schemes to augment the Labybower Reservoir reduced the flow of water. The building of Ladybower Reservoir in the late 1940s seriously limited water flow to the mill and the Eyres were awarded a total of £8000 compensation. In 1955 the east wheel, its associated millstones and the electric dynamo were demolished and the watercourse to the wheel was blocked up. Electric motors were added to supplement the water power by driving the provender equipment. In 1960 the ‘Limestone Pumping Scheme’ was introduced and took away more water from the mill. Additional compensation of £6000 was awarded, plus £750 to enable more electric motors to be purchased for mill. There were formerly three cotton mills at Brough. One was the later Brough White Lead Works (SK 182825). Another was near Brough House which now comprises cottages (SK 180824). The third was Stretfield or Brough New Mill (SK 178820); this was owned by Thomas Somerset until the business failed towards the end of the nineteenth century, reputedly because of the high cost of new machinery. The premises were subsequently in the hands of various owners and used for wire manufacture, for the making of combs from ox horn, as a cement workers’ hostel, and for other purposes. The mill continued to operate profitably through the 1950s but, in October 1967, following death duties imposed after Marmaduke died, and the changing market, William Eyre Junior reluctantly decided to bring the milling business to a close, part of the mill was changed to a shop in 1967 and later into agricultural merchants. was assessed (for tax) on a mill valued at £4-0-0 per annum. King John later gave the mill to Phillip, requiring that he provide a valet whenever the king came to the area to hunt. In 1421 the mill and various estates were granted to Richard Vernon of Haddon. By 1625 Brough Mill was owned by Rowland Moorwood of Castleton but was sold by him to the Eyres of Hassop Estates for £20-0-0 on the 3rd of May, 1625 and remained in their possession for 286 years. The mill is shown on Burdett’s map, and on most maps up to the present day.The three storeyed stone corn mill, with stone flagged roof, was also used as a saw mill, powered by one of the wheels. Millers included Ben Kirk in 1835, Sarah Kirk in 1842, with G. Mortimor in 1855. They were followed by Thomas Carter from 1876/81 but in 1885 the tenancy of the mill was taken over by William Eyre and in 1911 Hassop Estates decided to sell the mill at public auction when William purchased it for £1000.In 1900, William’s son Marmaduke joined the company and became a partner in Wm. Eyre and Sons. He was later joined by his brother William, who also became a partner in the business, and the mill continued lo thrive. However disaster struck when, in mid-winter 1924, a fire broke out in the mill, possibly starting from the kiln which was fuelled by gas, when some lead pipes melted. The building interior was virtually gutted, although both wheels were saved. Electricity was generated until around 1950 when abstraction schemes to augment the Labybower Reservoir reduced the flow of water. The building of Ladybower Reservoir in the late 1940s seriously limited water flow to the mill and the Eyres were awarded a total of £8000 compensation. In 1955 the east wheel, its associated millstones and the electric dynamo were demolished and the watercourse to the wheel was blocked up. Electric motors were added to supplement the water power by driving the provender equipment. In 1960 the ‘Limestone Pumping Scheme’ was introduced and took away more water from the mill. Additional compensation of £6000 was awarded, plus £750 to enable more electric motors to be purchased for mill. There were formerly three cotton mills at Brough. One was the later Brough White Lead Works (SK 182825). Another was near Brough House which now comprises cottages (SK 180824). The third was Stretfield or Brough New Mill (SK 178820); this was owned by Thomas Somerset until the business failed towards the end of the nineteenth century, reputedly because of the high cost of new machinery. The premises were subsequently in the hands of various owners and used for wire manufacture, for the making of combs from ox horn, as a cement workers’ hostel, and for other purposes. The mill continued to operate profitably through the 1950s but, in October 1967, following death duties imposed after Marmaduke died, and the changing market, William Eyre Junior reluctantly decided to bring the milling business to a close, part of the mill was changed to a shop in 1967 and later into agricultural merchants. |

|

Brough – New Mill SK178820 Stretfield or Brough New Mill was owned by Thomas Somerset until the business failed towards the end of the nineteenth century, reputedly because of the high cost of new machinery.

The premises were subsequently in the hands of various owners and used for wire manufacture, for the making of combs from ox horn, as a cement workers’ hostel, and for other purposes. The making of combs was also done in small water mills at the end of the nineteenth century. Meadows and Company occupied a former cotton mill at Stretfield, Brough, for this purpose for a few years, using cow-horn as their material. The premises were subsequently in the hands of various owners and used for wire manufacture, for the making of combs from ox horn, as a cement workers’ hostel, and for other purposes. The making of combs was also done in small water mills at the end of the nineteenth century. Meadows and Company occupied a former cotton mill at Stretfield, Brough, for this purpose for a few years, using cow-horn as their material. |

Brough – White Lead Works There were formerly three cotton mills at Brough. One was the later Brough White Lead Works (SK 182825), of which buildings still remain. Lead smelting was carried on through the second half of the nineteenth century and into the twentieth at the Brough White Lead Works (SK 182825). A lace-thread doubling mill in 1846, this was operated by Pearson and Co. In about 1860, Ashton had constructed the Brough White Lead Works (SK 182825) by adapting the disused cotton mill and after closure of the Marsh Green Cupola the whole business was transferred there, with the premises enlarged. Smelting was carried on day and night at Brough and refining effected by a Dutch process by which white, grey and red lead were produced. Production continued into the 20th century under Colonel Joseph Hall Moore, and ended in about 1924. Subsequently the premises were taken over by other firms and now comprise the steel finishing works of Messrs Cooke and Stevenson. Former buildings still exist and flues partially remain. A tail race, a remnant of the water power engineering, can be seen leaving the northern end of the mill. There were formerly three cotton mills at Brough. One was the later Brough White Lead Works (SK 182825), of which buildings still remain. Lead smelting was carried on through the second half of the nineteenth century and into the twentieth at the Brough White Lead Works (SK 182825). A lace-thread doubling mill in 1846, this was operated by Pearson and Co. In about 1860, Ashton had constructed the Brough White Lead Works (SK 182825) by adapting the disused cotton mill and after closure of the Marsh Green Cupola the whole business was transferred there, with the premises enlarged. Smelting was carried on day and night at Brough and refining effected by a Dutch process by which white, grey and red lead were produced. Production continued into the 20th century under Colonel Joseph Hall Moore, and ended in about 1924. Subsequently the premises were taken over by other firms and now comprise the steel finishing works of Messrs Cooke and Stevenson. Former buildings still exist and flues partially remain. A tail race, a remnant of the water power engineering, can be seen leaving the northern end of the mill.

A single storey building which has a clock in the motif of the Festival of Britain (1951) with figures spelling out (although not in the right order), ANAVIO, the Roman name for the fort at Brough [SK 182827]. The clock hands represent a Roman eagle and Roman fasces. Later Cooke and Stevenson Ltd made springs, flap valves, diaphragms, etc, from heat-treated steel strip and wire. Remains of the flues from the lead works can be found south of the works by the footpath from Brough to Bradwell at SK182823 to SK181821In places it is obvious that there was a double flue |

|

Buxworth – Britannia Mill SK017823 – a much earlier cotton-spinning mill became Britannia Wire Works Ltd and . Four storey, multi-ridged, gritstone mill by F.S.Gawthern, rebuilt in 1851, originally an early 19th century cotton mill serviced via the adjacent Peak Forest Canal. It had no connecting road towards Stockport and a private toll road, known as New Road, was built and opened in 1864 which today leads past the blue arches to Bridgemont on the A6. Tolls ceased in 1919. In 1903, the Britannia Wire Works Company took over the premises and later Meredith Spring Seat Co Ltd was founded and the site became well known for the manufacture of all types of seats. It ceased operating in 1969.

|

|

Calver Mill (SK 247745), formerly a cotton mill built on the site of a previous corn mill was used for filming Colditz and is now apartments. A smelting mill may have occupied the site in earlier days. It was built by the Gardoms, a family of hosiers, in 1785-6, at the time of expiration of Arkwright’s patents, the land being leased from Thomas Eyre of Hassop. The turn of the century was a time of misfortunes for the owners, then trading as Gardom, Pares and Company, for in 1799 a serious flood washed away Calver Bridge and caused havoc at the mill and in 1802 the mill was burnt down. In 1805 it was rebuilt, but because of family deaths and financial difficulties the Gardoms withdrew from the partnership and the management was taken over by a former employee, Horatio Mason, a benevolent and hard-working man who lived with his family at the mill house. About 200 people were employed at the mill in the 1830s, many coming from the neighbouring villages, others living near the mill. Mason was concerned for their welfare; educational facilities were provided for the children and a Sunday school established and conditions were generally less harsh than in many other factories of the time. Sadly, however, due to financial mismanagement, in 1839 Mason found himself bankrupt and running of the mill was taken over by Sir William Heygate, a member of the Calver Mill Company, followed in later years by a succession of others. Much of the yarn produced at Calver was sent to Leicester for use in the hosiery trade, and cotton spinning continued until the early 1920s when the mill closed down. During World War II the empty building was put into use as a storage depot while the yard became the scene of a crushing and washing plant for fluorspar. After the war the premises were bought by Mr H. G. Sissons, a director of Calver Mill Estate Ltd, and adapted for the manufacture of stainless steel sinks. The site has now been converted into apartments.

|

|

Castleton Corn Mill The former Castleton Corn Mill on the south side of Mill Lane at SK 151831 was used for grinding until the 1930s. Subsequently the 400-year-old limestone building was used as an antique store and then by the High Peak Mining and Engineering Company. In 1962 the premises were adapted and used by Cambrian Electronics Products Ltd but with preservation of certain mill features including the wheelpit. The former oak waterwheel of 10-12ft diameter was broken up in the 1950s.

|

| Castleton Saw Mill SK151831 – just north of the old corn mill is another building, about 300 years old, which was formerly a sawmill. |

| Chapel en le Frith Bowden Hay Wadding Mill SK062814 |

| Chapel en le Frith New Hyde Mill SK061807 – In 1846 it had a 24 hp steam engine, and John Ashton was spinning cotton. In 1857 a 30 hp engine was at work, and the mill was operated by the Misses Alice, Nancy and Sarah Ann Bennett. Later a wadding mill, it later became a shirt factory. |

|

Chapel en le Frith Paper Mills SK045822 – there was a group of six mills that was built here from the late 18th century. They are now overshadowed by the modern buildings of Glossop Super Alloys. The mill ponds were higher up the valley filled with water from the Shelf Brook. There was a report by Glover that John Ibbotson produced at Whitehough Paper Mills one single sheet of paper 1,000 ft long and 7 ft wide, c 1827.

|

|

Charlesworth Holehouse Mill SJ999922 -Renovated three storey gritstone 19th century former cotton mill, with square chimney and modern additions, in the same valley as Kinderlee Mill. The entrance road follows the stream from which a narrow leat takes water to a mill pond in front of the car park and a stone bywash takes surplus water back into the stream. In 2003 the mill produced “colours for industry”. In 1835 the mill was of either John Bowden or Joseph Cooper. In 1870 and 1891 it was in the possession of James Rowbottom, cotton spinner, doubler and cotton band manufacturer.

|

|

Charlesworth Kinderlee Mill SJ995923 – Four storey gritstone early 19th century cotton mill with blue slate roofs and round brick chimney, which straddled and completely filled a narrow deep valley formed by a tributary of the Etherow which comes down from Cown Edge. In June 2003, it was standing derelict and windowless but was in the possession of a property company with plans to convert it into about 50 units for housing. There was a mill pond.

|

|

Chatsworth Corn Mill – built in the mid-eighteenth century, the corn mill building is now a shell standing beside the River Derwent at SK 259688. From the weir across the river the head race, formerly controlled by a sluice, ran underground for a stretch and then in the open; the tail race discharged back into the river through a stone-walled arched culvert. The mill was last worked by Mr Wilfrid Johnson (previously by a George Hodkin) for grinding corn up to 1950 by Wilfred Johnson. |

| Chesterfield silk mill SK382708 – Markham Road. The Old Silk Mill was a four-storey brick building of seven bays. The mill seems to have lain idle for long periods but in 1846 George and Charles Tucker were silk throwster. It was demolished 1967.In his third volume Farey included seven silk-spinning mills in Derby and one in Chesterfield. This last, in Beetwell Street, was possibly the oldest surviving example of a water-driven silk-spinning mill until its demolition in 1967. Little is known about it, and research is needed to fill the gaps in its history. It was a compact building in brick, five storeys high, seven bays wide and three bays deep, with a low-pitched hipped roof. A stone embodied in the brick structure bore the date 1737, but this may have been removed from the adjacent bridge when it was modified; a reference by Dr S. D. Chapman to John White’s factory in Chesterfield may, however, confirm this date. White (1857) copied Bagshaw (1846) in including ‘a silk mill’ in the list of Chesterfield’s industries, but the unnamed author of The History of Chesterfield, 1839, in a sorrowful commentary on the lack of industrial initiative in the town, complained: ‘Chesterfield may boast of having a silk mill, carried by water, for a great number of years, yet nothing worth naming is done in the trade, though it would, perhaps puzzle anyone to advance a plausible reason why the manufacture of silk could not prosper as well here as Derby.’ |

| Chesterfield – Walton Corn Mill SK365706 |

| Chinley Bridgeholme Mill SK052817 |

| Chinley Corn Mill SK056817 |

| Combs Corn Mill SK045782 – The site of the former corn mill. |

| Combs Primrose Vale Mill The Primrose Vale Mills (SK 032879) were at one time a tannery, and also a buckram factory. The mill building, which stood bside the stream, is now completely removed. Workers’ cottages here are said to have been built in about 1860. |

Cressbrook Mill SK173726 Established for cotton manufacturing by Arkwright probably in 1783 in the parish of Litton – a locality already much involved with weaving, framework knitting and other textile skills. Here he leased land recently developed by John Baker, a hosier, who had, amongst other enterprises, started a small distillery for peppermint, lavender and other aromatic herbs which he cultivated. The date of the building of the first mill is uncertain, but it has been estimated as 1783, the work of construction having been put in the hands of William Newton, a self-educated poetic joiner from Cockey Farm, Abney. Soon after being built, the three-storeyed building was destroyed by fire on 15 November 1785, but rebuilding took place two years later on the same site. Water power at this stage was provided by the Cressbrook, water from the mill pond passing beneath the road and on to the mill before discharging into the Wye. After Arkwright’s death in 1792 the mill, used for cotton weaving, passed into other hands and in 1810 Newton came back as manager. The year 1815 saw the construction of the big mill building of Georgian appearance which now dominates the scene; this had two large waterwheels and was powered by the River Wye, dammed to form a mill pool in the limestone gorge. Later a steam engine was introduced to supplement the water power in times of drought and in about 1890 water turbines were installed. The mill continued in use for cotton doubling until 1965. Besides the big mill of 1815 the older one which replaced the original building still stands close by, together with the engineering shop which stands near the river at the end of a long low building on the south side, constructed in 1916. On the north side of the mill buildings there is a row of houses now known as Dale Terrace, but previously called Apprentices Row, where many of the apprentices lived. A portion at the end, of Gothic design, was possibly used as a chapel. Apprentice children at Cressbrook are reputed to have been comparatively well treated; they spent their limited free time at Leisure Farm on the hill above, and walked to Tideswell Church on some Sundays |

|

Cromford corn mill? SK293569. On the A5012 just above the lowest dam on Bonsall Brook, it was to drive a generator for a motorcycle business. The wheel is of 14 ft 7 in diameter, overshot, 30 rpm, with water conveyed through two iron pipes.

|

|

Cromford mill SK298569. Richard Arkwright bought the corn mill in 1771, with a lease of the land that Cromford Sough and Bonsall Brook ran through. In 1772 he erected his cotton mill, partly on the site of the corn mill, and worked it by a wheel turned by the water of the brook and the sough which was brought across the road in a wooden launder. This wooden launder was replaced in 1821 by a cast-iron one and later destroyed by a lorry. Water emerges from the mill by a culvert under the roadway, into an open channel and then to the canal. The original mill was six storeys high, but it has lost its two upper storeys, probably in the fire of 1890. A second mill was built in 1777, adjacent to the first one, later almost completely destroyed by fire. In 1789 Arkwright employed 800 people, but this establishment ceased work as a cotton mill in 1846.

|

|

Cromford Masson Mill SK294573 – Erected by Arkwright, 1783. The original six-storey brick building is at the north end of the present complex. There are impressive water works and an unusual down-curved weir at the rear of the buildings, seen only, by permission, from the left bank of the river.

In 1768, George White, who also held Lumb smelting mills, obtained a lease to build mills and erect wheels at the Masson, (SK294573), for ninety-nine years at �1 pa. In 1772 a grant was made to George White and Robert Shore to convey water to a paper mill for twenty-one years. This is the south weir at Matlock Bath, and was adjacent to Arkwright’s Masson Mill. In 1788 Shore, White and Swetnham were working the prosperous Llwyn Llwyd lead mine in Cardiganshire. In 1846, 320 were employed. The mill was sold to the English Sewing Cotton Co in 1897. The waterwheels were removed c1927. |

|

Curbar Corn Mill

Ruins beside the Barbrook (SK 275739) are of an old corn mill, disused for many years; it is believed that there was previously a lead smelting mill on the site. The former mill pond is still marked by a rushy area which often holds water. A stone bridge gives access across the stream from the direction of the A621 road. A drawing of 1869 shows a three storeyed building, complete with undershot wheel and the cowls of a kiln. The miller in 1895 was listes as Thomas Marples. |

|

Dale Abbey Windmill SK438398 – The Cat and Fiddle post mill, of 1788 or earlier, had a stone round-house added in 1844. It was the last surviving working mill in Derbyshire and was preserved by Stanton Ironworks Ltd.

|

| Danebridge Bearda Mill SJ963641- a former corn mill, is now a private house. |

| Danebridge Silk Mill SJ963651 |

| Darley Dale – Warney Mill SK275624 Situated on the Warney Brook at Darley Dale the mill operated until at least 1940. From 1891 to when it closed it was operated by James Walton & Co.The site is now owned by the DFS furniture store which was developed by Herbert Hardy. He lugged his suitcase from Darley Dale full of ladies stockings (and garments boys were not allowed to see) in the days before his enterprise grew into the DFS superstore.Not so long ago very few shops opened on Sunday because it was against the law to sell all but a limited range of goods and furniture wasn’t on the permitted list. Around 1970 Herbert Hardy overcame this by a clever plan to sell furniture on a Sunday by offering a free three-piece suite to anyone who bought a bag of carrots as it was permitted to sell vegetables. The carrots just happened to be the same price on a Sunday as the suites were on weekdays.  |

|

Diggle Mill SE017080 – Famed for the size of its waterwheel, Diggle Mill (SE 017080) was one of a number of woollen mills in Saddleworth. Diggle Mill was formerly a woollen mill with a very large waterwheel demolished in about 1920. Part of the original building was premises for a plastics factory. Reported in 2015 to now be housing.

|

|

Edale Cotton Mill

Edale Mill (SK 134854), powered by the River Noe, as well as having been a corn mill had also served as a tannery before being used for cotton. In 1795 Nicholas Cresswell enlarged the premises and took into partnership three Manchester cotton industrialists, James Harrison, Robert Blackwell and Joseph Fletcher, the main, larger mill building with its three storeys and external enclosed staircase probably being added at that time or early in the nineteenth century. Owned during the nineteenth century by Hector Christie, the mill in its later working days, like the one at Bamford, came under the firm of Fine Spinners and Doublers Ltd. Cotton manufacturing ceased here in 1934. Just west of the mill is the former manager’s house, now a private residence, and alongside the road are workers’ cottages. Many of the women who worked here, however, lived farther away; a number of them came from Castleton, walking to the mill each day. They walked 2 miles via Hollins Cross, a climb of 650 ft, to a height of 1,250 ft. In times of bad weather they would bring sufficient food for a few days and sleep at the mill. |

| Eyam Windwill There was formerly a windmill at SK 213766. Apparently of the tower type, it was demolished before 1877 after long being in disuse. Stone from its demolition was used for building a school. |

Fallgate Mill – Ashover Fall Gate Mill near Ashover located at SK 354623Probably been a water mill on the site from very early times, certainly from the early years of the 17th century.The mill is marked in Burdett’s survey of 1767 and on Greenwood’s map of 1825 but not on the first Ordnance map, although this is rectified in subsequent editions.When it was offered for sale in 1918 the Clay Cross Company recognised the potential of quarries on the land and purchased the site. They used the mill for grinding fluorspar, used in the steel industry in Sheffield, and in 1925 a spur from the Ashover Light Railway was built in front of the buildings to load the products of the quarries and the mill. The mill continued to be so used until the 1950s and the buildings subsequently fell into disrepair.In 1985 a 25 year lease on the site was taken by Ashover Parish Council and restoration work commenced under the Community Programme Plan. Fall Mill represents one of the few complete water powered corn mills in Derbyshire.The stone mill, kiln and living quarters were restored in 1986-87. Fall Gate Mill near Ashover located at SK 354623Probably been a water mill on the site from very early times, certainly from the early years of the 17th century.The mill is marked in Burdett’s survey of 1767 and on Greenwood’s map of 1825 but not on the first Ordnance map, although this is rectified in subsequent editions.When it was offered for sale in 1918 the Clay Cross Company recognised the potential of quarries on the land and purchased the site. They used the mill for grinding fluorspar, used in the steel industry in Sheffield, and in 1925 a spur from the Ashover Light Railway was built in front of the buildings to load the products of the quarries and the mill. The mill continued to be so used until the 1950s and the buildings subsequently fell into disrepair.In 1985 a 25 year lease on the site was taken by Ashover Parish Council and restoration work commenced under the Community Programme Plan. Fall Mill represents one of the few complete water powered corn mills in Derbyshire.The stone mill, kiln and living quarters were restored in 1986-87. The mill originally had two water wheels, but one has now gone, only a vestige of its wheel pit, scrape marks of the wheel and a cast iron feeder pipe from the dam remain. It was probably about 16ft. diameter and 5ft. wide. The other wheel has been restored and is about 14ft. diameter by 4ft. wide. It has an iron shaft, replacing an earlier wooden shaft, with iron arms and shrouds but with wooden buckets. This overshot wheel is supplied with water fed through a tall, vertical, iron pentrough.The small brick-built living accommodation, with a fireplace, is attached on the south side of building. It originally had an upper floor but this has now been removed, although the holes for the floor beams are visible in the walls. The ceiling of the lower floor would have provided less than 6ft. headroom. A large stone sink is still in place, the basin of which is only about 2ins. deep. The mill originally had two water wheels, but one has now gone, only a vestige of its wheel pit, scrape marks of the wheel and a cast iron feeder pipe from the dam remain. It was probably about 16ft. diameter and 5ft. wide. The other wheel has been restored and is about 14ft. diameter by 4ft. wide. It has an iron shaft, replacing an earlier wooden shaft, with iron arms and shrouds but with wooden buckets. This overshot wheel is supplied with water fed through a tall, vertical, iron pentrough.The small brick-built living accommodation, with a fireplace, is attached on the south side of building. It originally had an upper floor but this has now been removed, although the holes for the floor beams are visible in the walls. The ceiling of the lower floor would have provided less than 6ft. headroom. A large stone sink is still in place, the basin of which is only about 2ins. deep. |

| Fawfieldhead – Ludburn corn mill SK094620 |

| Fernilee Reservoir – Gunpowder Mill SK013771 Now lost under Fernilee reservoir – To comply with the 1772 Act, Derbyshire’s first application for a licence to make gunpowder came from Thomas Williamson of Shallcross in the hamlet of Fernilee in Hope Parish. Since the site, known as the Geldee Warth, the Mill Warth or the Warth-on-the-other-side-of-the-water was a safe thirty miles from any other gunpowder mill and twelve miles from Hope Parish church, the licence was granted on 26th December 1800. Thomas Williamson is known to have owned the mill until at least 1857 and one hundred men were employed at the works at one stage. The last owner, before closure after World War 1, was the Chilworth Gunpowder Company. |

| Fritchley Corn Mill SK361527 |

| Fritchley windmill – Fritchley windmill tower, South Wingfield is Grade II listed. There are significant remains of the stone roundhouse from the post mill with holes in the walls where the cross trees have been removed. It is located mid-way between Crich and Pentrich. The building listing is recorded as – |

|

Froggatt Slag Mill

Ruins at SK 247771 in Hay Wood are probably remains of an eighteenth-century slag mill. These consist of partial walls of a small building measuring 10ft 6in x 6ft 4m internally with walls 1 ft 9m thick. There is a 1 ft 6in wide opening in the front wall and in the one opposite a recess 2ft 6in wide, 5ft 4m high with a sloping back, evidently where the waterwheel was accommodated. At the higher level, water from a stream is diverted through open-ended stone troughs forming a launder, to fall into the ruined chamber. The gritstone sections of the launder are from 2ft 9m to 3ft 11in in length and have a square channel roughly 9m wide and 9in deep, with an overall width of 1ft 8in. Smelting is believed to have been done here. |

|

Glossop Cotton Mills SK029942

The complex of Wrens Nest was begun 1815 by Mathew Ellison, agent to Lord Howard. In 1827 his relative Francis Sumner joined him and began the great expansion of the works. The early dam and old buildings stood at the western end of very large spinning mills and weaving sheds of later dates. It was a Catholic firm and brought many girls from Ireland to work in the mills. In 1830 John Wood moved from the Water Mill into Howard Town (ie the Glossop of today), initiating the other major establishment which later specialised in Two Cities fabrics.Later still Wood Brothers Ltd was spinning cotton and rayon. Many new industries were introduced, eg crepe rubber, plastic products and animal foods, which occupied parts of the large factories. In 1948 Sumnadale fabrics were being produced. Glossop had only one textile mill in 1774: by 1809 there were 54, half of Derbyshire’s total at the time, strung along the six brooks that focus on the town. |

| Glossop Cowbrook Mill SK049940 – was in ruins in 1965. |

| Glossop Dove Mill SK035927 – Dove Mill was a wool-carding and fur-blowing establishment with a dam fed by an underground leat. It was operated by Joseph Bennett in 1857and later it became a paper mill. |

|

Glossop Gnathole Mill

At the beginning of the nineteenth century a small number of woollen mills came into existence in the district now covered by the national park. One of these was Gnathole Mill, Charlesworth (SK 039924), built in 1790 by John Robinson on the site of an earlier corn mill and because of its peaty water said to have been renowned for the quality of broad cloths and narrow cloths it produced. Woollen manufacturing was carried on here it seems until about 1880, since when an older building has been adapted for agricultural purposes and the later main mill and offices converted to four flats and a farmhouse. In the centre of this structure is the site of the waterwheel, the power of which was later used for cutting firewood and, more unusually, for churning butter. The water came from Bray and Whitethorn Cloughs and was stored in ‘lodges’-a term for millponds used in this area. |

|

Glossop Howardtown Mills SK 035939-039939

These mills consisted principally of two large separate five storey gritstone buildings, mainly spinning blocks, but there were also some low weaving sheds along the north side of Giossop Brook and a round brick chimney at the eastern end. The first mill on the site was a fulling mill of 1783 and this was changed to a spinning mill by 1811. John Wood purchased the mill in 1819 and developed a vast vertically integrated cotton firm on the site which finally shut down in the 1960s. There are entrance pillars and a gatehouse (Listed Grade II) at the Victoria Street entrance. The former owner’s residence was ‘Howardtown House’ on the south side of High Street East. |

| Glossop Hurst Mill SK049940 – was a small early 19th century two storey gritstone cotton mill located on Giossop Brook. |

| Glossop – Mill reservoir SK018897 – The garden pond of Grove House was one of the former Rowarth mill reservoirs. Through the gate was the site of Top Mill which had closed down by the 1860s, and whatever was left of it was destroyed in the 1930 flood. |

| Glossop – Mill reservoirs SK015900 a string of reservoirs built in the early 19th century in the valley of Rowarth brook to provide a regular supply of water for the mills. |

| Glossop – Old Glossop Mills SK045948 – demolished in 1965. |

| Glossop Paper Mill – At Fair Vage Clough (SK 079990) was a former paper mill. |

| Glossop Paper Mills SK033931 |

| Glover’s Mill SK312218 |

| Glutton Bridge Corn Mill – A corn mill on the River Dove at Glutton Bridge (SK 084665) was demolished in the 1940s. |

| Gradbach Mill SJ994661 Flax growing and processing received encouragement during the reign of George III through imposition of duties on foreign linen and the provision of bounties to boost the growth of hemp and flax in this country, and also from the patenting by the flax spinners Edward and James Dakeyne of their water pressure ‘disc’ engine in 1830. At this time two mills in the district manufactured flax: the Upper Hulme Mill in Leekfrith parish and the one at Gradbach (Quarnford), mentioned in 1834 as being occupied by the flax spinner Daniel Dakeyne. Both mills were later used for silk. The Gradbach mill was originally built in the eighteenth century or earlier and restored after a fire of 1785. The rectangular two-storeyed building, constructed of millstone grit and, like the mill at Wildboarclough, using cast-iron columns for internal support, had at one end a section which contained the waterwheel. This was very large – of 38ft diameter and equipped with 96 buckets, each holding 35 gal. Such was the arrangement of gearing that one revolution of the wheel is said to have turned the main shaft 2,500 times. Many of the people who worked in the mill lived in a small industrial village settlement which then existed in the valley. This consisted of many cottages which are now demolished, their traces still remaining in places between the mill and Manor Farm. Silk production at Gradbach ceased in the early 1870s and the premises were acquired by Sir John Harpur Crewe, and used it as a saw mill and for joinery. It is said, a young girl was trapped in the mill wheel and crushed to death and from that day forth, as the wheel turned her cries could be heard. |

| Grangemill Corn Mill – A building at SK 243577 was formerly a corn mill. Dating from at least as early as the eighteenth century, it has not been used in living memory and the waterwheel no longer exists. |

|

Great Shacklow wood – On the south bank of the River Wye at (SK182696) where the footpath crosses the river, there are two buildings which were formerly a bone mill but more recently used for timber. By the side of one building are two external iron waterwheels, the mill leat comes from a nearby weir close by up stream. |

| Grindon Ford Mill SK067534 – A former corn mill which has been disused since about 1900. |

|

Goytsclough Mil – At SK 012733, near the quarry, is the site of the former Goytsclough Mill, built as a stone finishing mill and later used as a paint mill. Water was taken by leat from the Goyt and also from a stream in Deep Clough and held in a dam for powering the waterwheel. There were formerly also cottages here for employees. Now both mill and cottages have been demolished.

|

| Hadfield Mill SK027962 – The mills of Thomas and William Platt (1835-1891). Two storey 19th century gritstone mill buildings with flat roof. |

| Hadfield Waterside Mills SK019967 – Early 19th century gritstone mill buildings, some had cast-iron window frames. The site was developed as the Hadfield Industrial Estate. These were the extensive cotton spinning mills of the Sidebottom family, and later Garside and Co. |

| Hadfield Wren Nest Mills SK028942 – The complex of Wrens Nest was begun 1815 by Mathew Ellison, agent to Lord Howard. In 1827 his relative Francis Sumner joined him and began the great expansion of the works. The early dam and old buildings stood at the western end of very large spinning mills and weaving sheds of later dates. It was a Catholic firm and brought many girls from Ireland to work in the mills. In 1830 John Wood moved from the Water Mill into Howard Town (ie the Glossop of today), initiating the other major establishment which later specialised in Two Cities fabrics.Later still Wood Brothers Ltd was spinning cotton and rayon. Many new industries were introduced, eg crepe rubber, plastic products and animal foods, which occupied parts of the large factories. In 1948 Sumnadale fabrics were being produced. Glossop had only one textile mill in 1974: by 1809 there were 54, half of Derbyshire’s total at the time, strung along the six brooks that focus on the town. |

|

Hartshorne Screw Mill SK325214 – In 1760 Job and William Wyatt of Tatenhill in Staffordshire, took out a patent for a method of cutting wood-screws on a lathe. Their business was taken over soon after 1776 by Shorthouse Wood and Co, who set up a factory at Hartshorne. Known as the Screw Factory, it was operated by a wheel on Repton Brook, and it must have been one of the first establishments to be concerned with the continuous mass-production of small components. By 1796 it was employing fifty-nine workers, and reported to be turning out 1,200 gross of screws per week on thirty-six lathes worked by the one waterwheel. Stebbing Shaw, the onetime rector of Hartshorne, described the lathes as producing eight or nine screws per minute, the operations requiring the stopping and starting of each lathe eighteen times per minute. Children were employed, and they could earn from is 6d to 1s9s per week. It is difficult, however, to reconcile the rate of production with the total output, which would be expected to be about three times as great as quoted. In 1846 the works was shut down, apparently because it could not compete with the Birmingham firm of Nettlefold and Chamberlain, which had adopted new American machinery.

|

| Hartington Corn Mill SK120598 – The mill is converted into a dwelling house and said to date back 400 or 500 years. Latterly the mill was worked by Messrs Caudwell; it was used during World War II for grinding farmers’ oats. |

| Hartington Crowdecote Mill SK100651 – marked on Greenwood’s 1825 map but it is not clear when ot stopped working. |

| Hartington – Ludwell corn Mill SK124623 – Long since incorporated into farm buildings. |

|

Hathersage – Dale Mill SK235817 – Believed to have originally been used for wire-drawing though it has served various subsequent purposes including button-making, engineering, shoe-making and timber. The main building is three-storeyed, with a square chimney stack, and on the opposite side of the road are cottages which were formerly connected with the mill.

|

| Hathersage – Green’s House Paper Mill Remains of an old paper mill known as Green’s House Paper Mill can be seen at SK233837. It was worked in the 1840s by Charles Ibbotson to make shop and factors’ paper. In 1857 it was occupied by Charles Marsden ‘manufacturer of coarse brown paper’ but production ceased long before the end of the century. Parts of the walls of the buildings remain on level ground beside the stream, one having covered an area of approximately 40 x 20ft. On a higher level, behind an apparently natural dam, is the millpond, still holding water fed by springs above and discharging to the stream, with grooves for the sluices still visible. A stream of water continues to fall beside walling where the waterwheel was situated. |

|

Hathersage Haselford Mill Lead mill (SK 233807), beside the River Derwent, is now a private residence. It may at some time have had a purpose connected with lead, but is known to have formerly been a corn mill, and latterly a stonemason’s yard using water power for sawing and dressing stone. An advertisement in the Derby Mercury in 1782 offered a mill, called Hasleford Mill for sale, occupied by Mrs Hinch. This was called ‘Haxelford Mill’ on Greenwood’s map of 1825 and is currently known as ‘Lead Mill House’.

|

|

Hayfield Bank Vale Paper Mill SK031875 – Bank Vale Paper Mills of John Slack Ltd , established in the early 1800s. The mill is the southernmost of three former mills on a tributary of the River Sett. The site has been involved in paper manufacture since it was built in the early 1830s. Higher upstream was a stone-faced reservoir and a stream with a series of weirs controlling the flow into a headrace. Adjacent was the former mill owner’s house, Oaklands.

|

| Hayfield Fulling Mill SK055863 Situated near The Ashes on the western slopes of Kinder Scout, operated from early times to the beginning of the nineteenth century. |

| Hayfield Phoside Mill SK037859 – Used in the early 1800s for yarn spinning, weaving and cloth dressing. The former mill building is still in existence on the hillside and is now a barn, the waterwheel having been removed in the 1920s. |

| Hayfield Primrose Mill SK031880 – a small former buckram mill, which was the second mill on the small tributary of the Sett. There was a chimney built on the hillside behind the terrace of stone cottages to provide draught. |

|

Hayfield Walk Mill SK037870 – To the west of the bridge in the centre of the village was the site of a water-powered fulling mill on Phoside stream which runs under the house: the remains of the building are now incorporated in a private house, ‘Grotto House’. Such a mill was known as a walk mill when the cloth was ‘walked’ under bare feet in a trough of water in a liquor containing fuller’s earth.

|

|

Heage Windmill SK366358 – Grade 2* Listed – open to the public – see their website for details After a partial restoration by Derbyshire CC, the current owners, she was restored to full working order in 2002 by the Heage Windmill Society, aided by financial grants and much hard work from a team of dedicated volunteers. Apart from work on the windmill itself a new access road from Chesterfield Road, and a large car park, were built; water and electricity were brought to the site. With her squat stone tower, white cap, and six sails turning gently in the breeze she is a glorious site to behold! She stands on a grassy mound and there are three floors, full of old machinery, whilst below is a basement, where displays tell the story of the mill. The windmill is run as a charitable venture and is operated by a team of largely local volunteers who operate and maintain her, carry out all milling operations and also act as guides. Flour produced in the mill is only sold in the mill shop and at Farmers Markets in Bakewell and all profits go to keeping the mill running. visit the Heage windmill website to learn more. |

|

Higham Corn Mill SK386584

At Dairy Farm, a three-storey sandstone building, with cast-iron windows. A water mill is mentioned by Farey, and Sanderson’s map, 1834, shows it as a bump (candlewick) mill. Occupied by Fred Turner (Hosiery) Ltd. At other times it has been a corn mill, a mustard factory and a jam factory. It had a 16ft waterwheel. |

|

Holmbridge Rake Mill SE105055 – At Holme the Bilberry fulling mill and two other woollen manufactories stood in the area now covered by the Digley Reservoir. There was also a small woollen mill called Rake Mill which was used for spinning yarn for the local weavers.

|

|

Hope Corn Mill SK173838

The former Hope Corn Mill (SK 174838) on the River Noe was in 1969 converted to a dwelling house after being disused for a number of years. The date 1866 on the main building probably indicates its renovation, or addition to an older building adjoining, undoubtedly the earlier mill. The letters JRC are believed to have been the initials of a John Robert Cocker of Hathersage. Threshing was done at the mill and the corn dried by coke fires before being ground. The building was also used as a sawmill, with a subsidiary wheel at the front taking power from the main waterwheel. The waterwheel, of about 11ft diameter and 3ft width, has been dismantled and removed. While the wheelpit no longer exists and the leats and pond have been rendered at least temporarily dry, various mill features have been preserved and blended into the reconstruction. This mill, converted to a house, can be approached along a public footpath from a track which leaves the Edale road at SK 172839. On the left of the footpath is a man-made watercourse taken from a tributary of the Noe leading to a mill pond now in the garden of the house. An old water wheel – relocated from the east end of the mill – stands in a pit’ by the side of the river. |

| Ible Corn Mill SK246569 – was in use until about 1900 – possibly dates back to the early 1700’s and worked until aboyut 1900 . |

|

Ironville Forge and Rolling Mills SK443513

Established by the Butterley Company in 1807, the Codnor Park works was producing wrought iron by the Cort process until July 1965, being demolished in 1966. The puddling process was filmed in 1964. A long masonry bank formerly surmounted by three 40 ft-high blast furnaces still stands. These were using hot blast in 1835, within two years of the Neilson patent. for the Cort process see – http://en.wikipedia.org/wiki/Puddling_furnace#Puddling_furnace http://en.wikipedia.org/wiki/Henry_Cort |

|

Kettleshulme Lamb Hole or Lumb Mill (SJ 988804) was the site of a former cotton mill destroyed by fire in the 1820s. The shell of the burnt-out building was bought by a Mr Sheldon who reconstructed the present gritstone building in 1835 and adapted it for making candlewick for miners’ lamps. The manufacture continued, providing the main source of local livelihood, until World War I when demand for candlewick declined. The premises were subsequently used for a time for making linen sheets. Originally lit by oil, the mill manufactured its own gas supply for lighting purposes until changing to water-generated electricity.

|

|

Little Hayfield Clough Mill SK032882 Originally a cotton mill dating in part from the 1830s and later, when steam power was introduced. Substantial rebuilding took place in the 1870s, however, following a fire. Clough Mill was a cotton-spinning mill, one of many which grew up at the time in this district and in the Glossop locality. The mill saw stormy patches, with riots in 1830 and distress at the time of the ‘cotton panic’ in the 1860s caused by the blockade of American southern ports. The manufacture of cotton ceased in 1920 and since then the buildings have been used for different purposes.

|

|

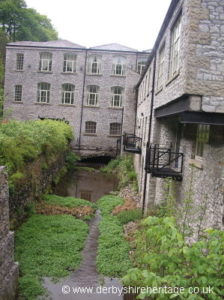

Litton Mill SK161729 Litton Mill was opened for cotton spinning in 1782 by Ellis Needham, a notoriously mean character. Mainly due to labour problems, pauper apprentices were brought from London and other cities to work long hours in the mill and to endure the poor food and harsh and rigorous treatment for which Litton Mill was noted. In 1815 Needham was bankrupt. The mill was subsequently run by others, one being Henry Newton (son of William) and was described in 1857 as an ‘extensive spinning and manufacturing establishment’ with 400 people employed and using water and steam power. There was a fire at the mill in the 1874 and most of the present buildings are of more recent date, although a building at the bottom of the yard is believed to have been part of an old warehouse, and another, which stands on stone pillars at the higher end, was probably a coach house. In 1934 Litton Mill was bought by the Anglo-French Silk Mills Ltd, and subsequently run as Litton Mills Silk Mills Ltd; artificial silk was produced, and later man-made fibres. A further change of ownership occurred in 1963 when textured yarns were manufactured.

|

|

Longnor Mill SK085646 – Situated by the River Manifold in the parish of Heathylee (SK 085646), the mill seems to have had a varied history. It is believed originally to have been a corn mill, later used for grinding bones, and in the 1930s was the scene of a fire. Wooden hay racks were made in more recent years and the premises was also used as a saw mill by the Harpur Crewe estate. Its overshot waterwheel, of approximately 14ft 6in diameter, 5ft 6in wide, had wooden spokes and iron buckets.

|

| Low Bradfield – Corn Mill – the former Low Bradfield Corn Mill (SK 264918) was burnt down in 1940. Further north there was another mill, submerged by construction of the Broomhead Reservoir |

|

Mellor Cotton Mill SJ967885 – In 1792 Samuel Oldknow designed and built a large cotton-spinning mill on the Goyt, helped financially by Richard Arkwright. It was burnt down in the 1890s, but a contemporary painting shows a resemblance to the frontage of Willersley Castle; 120 hp water power, of which the tunnel leats can be traced in the ruins. In 1857 it had combined steam and water power of 300 hp. The dams are now the Roman Lakes. After considering the use of iron, Oldknow built the elegant single-arched bridge over the Goyt in stone. On Oldknow’s death the mill was taken over by Arkwright II. It remained in use until the fire. Bottom’s Hall, now a farm, was reputedly the Apprentices’ House. The MAT Mellor Archaeological Trust are currently working on the site. MAT link |

| Matlock Bottom Mill SK304597 There has been a mill at Matlock Green since about 1374. In the 18th century the mill was owned by Joseph Blackwell and was known as Bottom Mill. |

| Matlock Lead Smelting Mills SK309607 – By Hurst Farm were the Lumb smelting mills, owned by George White in 1768. |

|

Matlock Green Corn Mill SK309599 – a large tall corn mill, formerly Gartons and E H Bailey Ltd., of 1799 date (Pevsner). Probably dating back to the late 18th century, it was built for Samuel Unwin. A steam engine was added in the late 19th century and roller miiling was introduced at about the same time.

|

| Meerbrook Corn Mill The former corn mill at Meerbrook (SJ 993607) was demolished prior to the area being flooded by the enlarging of the Tittesworth Reservoir in the early 1960s. |

| Middleton Corn Mill – tThere was formerly a corn mill at SK 199636 on the River Bradford, where its site is marked by some slight ruins. |

|

Millford Mills SK351452 – On either side of the stone bridge over the Derwent in 1790 were the extensive cotton-spinning, bleaching and dyeing mills built by Jedediah Strutt from 1780 onwards. The old mills south of the bridge were demolished in 1964. Fortunately they were fully documented by Johnson and Skempton. Stone from Hopping Hill Quarry, (SK352453), was used for the mills. It was exceptionally difficult to work but was beautifully dressed, and the buildings were difficult to demolish. Examples of William Strutt’s fireproof design, with cast-iron stanchions and beams, hollow earthenware pots and plaster flooring, have been preserved locally and in the Science Museum. The mills were light, airy and warm.

|

| New Mills Albion Mills SJ996848 – 3 and 4 storey gritstone mill building of 1859. This was the first of a group of 19th century cotton mills erected around the Peak Forest Canal at Newtown. In complete contrast to the mills in the Torrs, this is not a water power site, the mills dating from the steam-powered era, using the canal for water and cheap supplies of coal. |

| New Mills Brunswick Mill SJ997849 – 3and 4 storey gritstone mill building (datestone 1883) on the banks of the Peak Forest Canal, formerly a cotton mill, but was extended and used as a sweet factory by Swizzels-Matlow. |

|

New Mills Hyde Bank (Beard) Mill SK001856

Four storey gritstone former cotton mill on Hyde Bank Road standing astride the R.Sett: rebuilt after a fire in the early 19th century on the site of an early woollen mill. There are two arches under the mill, visible from the road, one spanning the river and the other the former head race. Now in multiple occupation. |

| New Mills – Bower or Salem Mill SK002858 – Two storey gritstone buildings formerly a cotton mill of the 1780s and later a chemical works. It was built adjacent to the Duchy of Lancaster’s medieval manorial corn mill. |

| New Mills Torr Mill SK001853 – a small water-powered cotton mill at the confluence of the rivers Goyt and Sett, dating from 1794. In the mid 19th century it was extended and converted into a steam-powered five storey mill which was destroyed by fire in 1912. |

| New Mills Torr Vale Mill SJ999854 This gritstone mill, on a bend of the R.Goyt, consisted of a four storey spinning mill, a three storey “old mill’ (originally from 1788-90), a link block, the shell of a former four storey weaving block, a mill chimney and offices. In 1788-90, there was a weir, a watercourse cutting through the promontory on which the mill was built, a footbridge over the river and two other buildings. The mill was weaving towelling products when it closed at the end of 2000. The weaving shed was destroyed by fire in August 2000. |

| One Cote Corn Mill SK047554 – A building near the village, at SK 047554, was formerly a corn mill. |

|

Over Haddon – Carter’s Corn Mill SK184657

Now demolished, Carter’s Corn Mill was a corn mill dating from the early nineteenth century. Although long in disuse the building still stood up to World War II when the waterwheel was removed for scrap. Subsequently the walls disintegrated and most of the stones were removed. |

| Over Haddon Sough Mill – Sough Mill, close to Lathkill Lodge (SK 203662) dated at least from 1529 and was worked until the early nineteenth century. |

| Padfield Cotton Spinning Mill SK032960 |

| Peak Forest Corn Mill SK115787 – located behind The Devonshire Arms pub. |

| Peckwash Mill – information provided by Philip Parkin

SK 363420 52°58’36.0″N 1°28’29.8″W Earliest site references are of a corn mill in the 13th century. In 1425 the mill owners were granted a charter granting the right to take water from the Derwent to drive the millstones. Paper making mill. Thomas Tempest acquired the mill in the latter half of the 18th century. In 1805 he had a charter of 1425 renewed. Also obtained the right to take 800 hp from the Derwent. Installed a Fourdrinier machine in 1821. By 1850 Tempest had installed 5 large waterwheels. It was possibly the biggest paper mill in the country at this time. At its peak it had four paper making machines running – said to be the only such mill in the world. By 1889 it had its own railway branch line. Tempest built the current mill in preparation for the Fourdrinier machine. In was completed by 1821 and constructed from stone taken from a quarry on the hillside directly above the mill. Cottages for workers were built on the hillside above the mill between 1820 – 1850. These are now known as the Blue Mountains cottages. the earliest of which are the two-storey ones at the northern end of the row. Ref. “The Industrial History ofDerbyshire” by Frank Nixon . David and Charles 1969 Unfortunately, although the mill building is still standing, it is difficult to take satisfactory photos as it is now surrounded by trees which guard the privacy of the private residence that it has become. |

| Pentrich Mill SK377520 – corn mill which was rebuilt in 1878 on an old site. Has also been a lace mill. ‘French’ stones were used. |

| Pentrich Weir Mill SK377520 – Weir Mill is sometimes incorrectly recorded as Wire Mill. A corn mill on the Amber, recorded by Farey, 1807. |

| Pott Shrigley – Pott Mill SJ947797 |

|

Rainow Cotton Mill

At Mill Brook (SJ 949757) there was a cotton mill, said to have been burnt down three times, the last time in about 1868. The proprietor was a Stephen Sheldon whose son brought the raw cotton from Manchester by waggons and teams of horses. After the last fire a portion of the buildings was rebuilt and used by another firm as a fustian-cutting room. There was formerly a very high chimney. There are no remains of the mill. A water pumping station now occupies the site; when foundations for this were being dug a pipe, believed to have been for gas, was discovered from which it is conjectured that the mill had gas lighting. |

|

Rainow Gin Clough Mill – Run in the nineteenth century by James Sharpley, a silk throwster, whose supplies of silk were brought from Macclesfield by pannier donkeys. Production ceased apparently in the 1860s after which the premises were adapted for use as a wheelwright’s shop.

|

| Rainow mill workers’ path SJ945768 |

| Rowarth Grove Mill – Rowarth Grove Mill was said to have been a calico printing works. |

|

Rowarth Little Mill

There were five cotton mills in the valley at Rowarth in the early nineteenth century; in 1857 there were two cotton mills and one paper mill but by the end of the century there were none. SK011889 is the site of cotton mill which was possibly the earliest in the New Mills area. It was a separate two-storey building from the inn, in between the brook and the inn. In a disastrous flood of June 1930 resulting from a tremendous thunderstorm, the mill and the remains of the water wheel were completely destroyed. |

|

Rowsley Caudwell’s Corn Mill

The Rowsley Corn Mill (SK 255657) is owned by the Haddon Estate and has been run by Messrs Caudwell Ltd as a flour mill since the present building was constructed in 1870 or 1871. It is believed there was previously a sawmill on the site, but many records were unfortunately burnt in the inter-war years. Buildings on the south side are apparently older than the main one. There is no memory of the waterwheel but its position and marks left by its use are still visible; evidently undershot, it must have been of 12-14ft diameter and of about the same width. The waterwheel has long been replaced by turbines, the present two, of 80 and 50hp respectively, both about 50 years old, are still powered by the River Wye. Milling is now performed by rollers in place of the original stones; flour is milled and maize and barley are ground, and animal feeding stuffs are made up to supply various products for which the firm is agent. |

|

Sheen Brund Mill SK099613 – There was formerly a corn mill on the site but from the end of the eighteenth century the premises comprised a cotton factory, believed to have been leased by a Thomas Cantrell and used by him and his three sons for cotton spinning and calico making. Since that time the building has reputedly been used as a sawmill, and during wartime for grinding corn.

|

| Sheldon Mills Two buildings on the south bank of the River Wye (SK 182696), the more westerly of them still retaining two external iron waterwheels, formerly comprised a bone mill and were latterly used for timber. The leat is still traceable coming from the weir across the river a short distance upstream.Close to the river, beside the mill buildings just described, is a pumping house and small waterwheel used in the past for raising spring water to Sheldon village. |

| South Normanton Windmill SK436562 – heavy timber framework of the post mill. The earliest date recorded is 1794, but it was shown on Burdett’s map of 1767. According to Mr J. C. Williams, this may be the mill mentioned in 1699. |

| South Wingfield – Wingfield Park Mill SK372540 – Wingfield Park Mill was a lace-thread spinning mill in 1816, it had two dams. |

|

Spancarr tower mill – Spancarr tower mill at SK341660 by the A632 Matlock road with its conical six sided roof underwent conversion to a house around 1996. The kiln remains were incorporated intro the building.

|

| Stanton Corn Mill SK233639 – the building was in ruins in 1971. |

|

Stoney Middleton Carters Corn Mill

The former Carters Corn Mill (SK 230755), with water still rushing down at its side although the waterwheel was removed by early this century. It had for many years been a footwear factory and was believed to have been connected with the Grindleford tannery, the shoes produced being taken to Chesterfield to be sold. There were four or five boot-making concerns in Stoney Middleton, all now having ceased to function. A building on the south side of the main road in the village (SK 229755) was used as a shoe factory until the 1960s. |

| Stoney Middleton – Lord’s Smelt Mill and cupola A cupola apparently preceded by a smelt mill was at Stoney Middleton (SK 224756). This was formerly known as the Lords’ smelt mill and was used mainly by ore-burners and ore-buyers working independently; from 1840 the cupola was taken over as a rock mill for crushing barytes for paint making. |

| Tansley Bobbin Mill SK322604 – A small bobbin mill, owned by Edward Radford, who had a large spinning and candlewick mill. |

| Tansley Spinning Mill – The first spinning mill was built by Samuel Unwin of Sutton-in-Ashfield, at SK318599: a gritstone building of three storeys, sixteen bays, with plain rectangular cast-iron windows. Later it was used as a smallware factory, a tape mill, a joinery and a store. |

| Tansley – Tansleywood Mill SK313601 – A small bobbin mill owned by Edward Radford, who also had a large spinning and candlewick mill, the Tansleywood Mill. |

| Tansley – Top Mill SK320599 – comprised three storeys, eight bays, and was owned by the Unwin family. Water led to an overshot wheel (inside the main building) by a cast-iron pipe supported on a three-arched stone wall. |

|

Thorpe Corn Mill SK146505

Thorpe Corn Mill on the River Dove (SK 146505) has been completely demolished. The mill was last worked in about 1893. The village water mill, which was situated on the River Dove, has completely disappeared although traces of the waterways can be found. However, the name is maintained in Thorpe Mill Farm close to St. Mary’s Bridge in Ilam. J. Hodkinson was the miller 1857 -1881, followed by Richard Radcliffe, who was last recorded in 1904. |